Stainless Steel 310 Wire Mesh

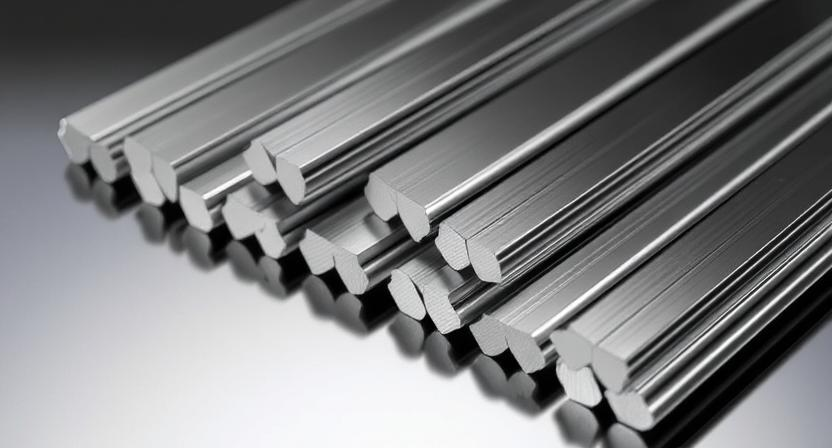

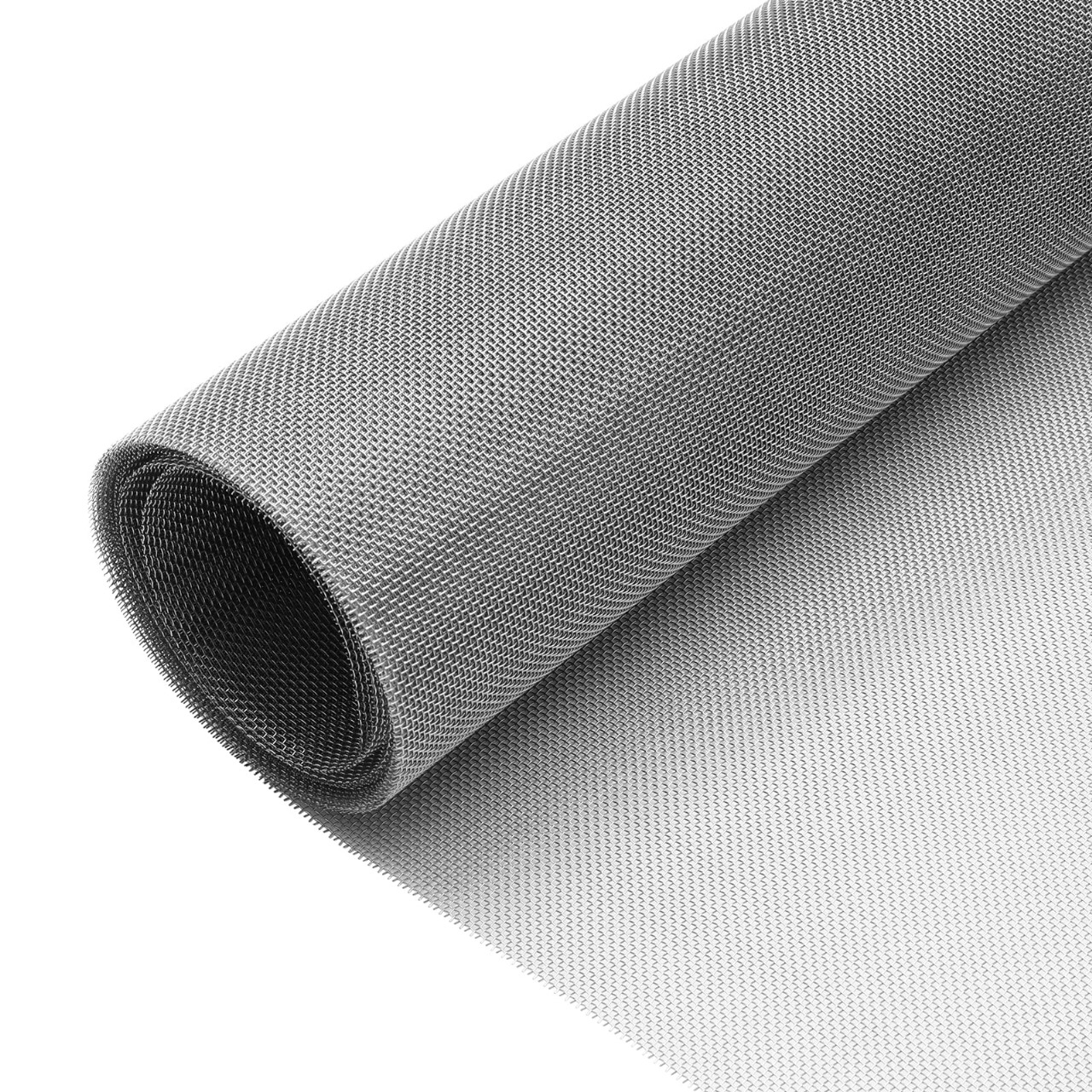

Ferrrobend has established itself as a leader in manufacturing stainless steel 310 wire mesh. This material, known for its remarkable heat resistance and corrosion properties, has become a top choice for industries that demand strength and durability in extreme conditions. In this article, we will delve into the advantages, uses, and manufacturing process of stainless steel 310 wire mesh by Ferrrobend, highlighting why it is an essential material for various applications. Stainless steel 310, also referred to as SS 310, is an austenitic stainless steel alloy with a high percentage of chromium and nickel. This alloy is well-known for its excellent resistance to oxidation and corrosion, making it ideal for use in high-temperature environments. The wire mesh made from this steel combines these properties with the versatility and practicality of a woven wire fabric, allowing it to be used in a variety of demanding applications.

Ferrrobend employs advanced techniques and high-tech machinery to ensure the precision and quality of every stainless steel 310 wire mesh product. The company uses state-of-the-art weaving machines that produce mesh with uniform apertures and consistent wire diameters.

Ferrrobend understands that each industry and application has unique requirements. That’s why they offer customized solutions for their stainless steel 310 wire mesh products, including specific wire diameters, mesh opening sizes, and overall dimensions. Customers can choose from a wide range of options to suit their exact needs.

At Ferrrobend, quality is paramount. The manufacturing process includes rigorous quality control checks at every stage, from raw material sourcing to the final product. This ensures that each stainless steel 310 wire mesh product meets the highest industry standards and performs reliably in its intended application.

After the mesh is woven, the next step is finishing, where the mesh is cleaned, inspected, and tested. Ferrrobend ensures that the mesh meets all required specifications before cutting it to the desired size and shape. Before the stainless steel 310 wire mesh leaves the factory, it undergoes a rigorous quality control process. Ferrrobend conducts a series of tests, including tensile strength, aperture size, and surface finish checks, to ensure the mesh meets the highest standards.

Stainless steel 310 wire mesh manufactured by Ferrrobend is a high-quality, durable solution for industries requiring reliable performance under extreme conditions. Its excellent heat resistance, corrosion resistance, and strength make it suitable for a variety of applications, from filtration and screening to security and aerospace. With Ferrrobend's expert manufacturing process, custom solutions, and dedication to quality, businesses can trust that they are investing in a product that will deliver consistent, long-lasting performance.