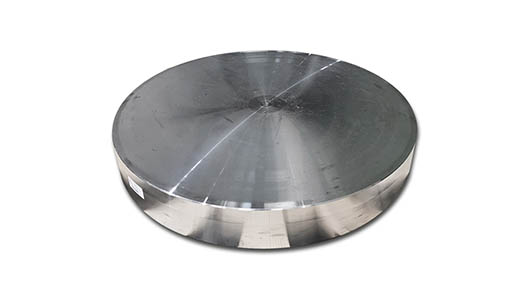

Stainless Steel 310 Forged Discs

Stainless Steel 310 forged discs are an ideal solution. Ferrobend, a leading manufacturer in the forging industry, specializes in producing high-quality Stainless Steel 310 forged discs designed to meet the demanding needs of various sectors, including aerospace, automotive, petrochemical, and power generation industries. In this article, we will discuss the key features, advantages, and manufacturing process of Stainless Steel 310 forged discs, with a focus on how Ferrobend's expertise delivers outstanding products that meet global standards. Stainless Steel 310 is specifically designed to withstand temperatures as high as 1100°C (2012°F), making it an ideal material for high-temperature applications, such as in furnaces or exhaust systems.

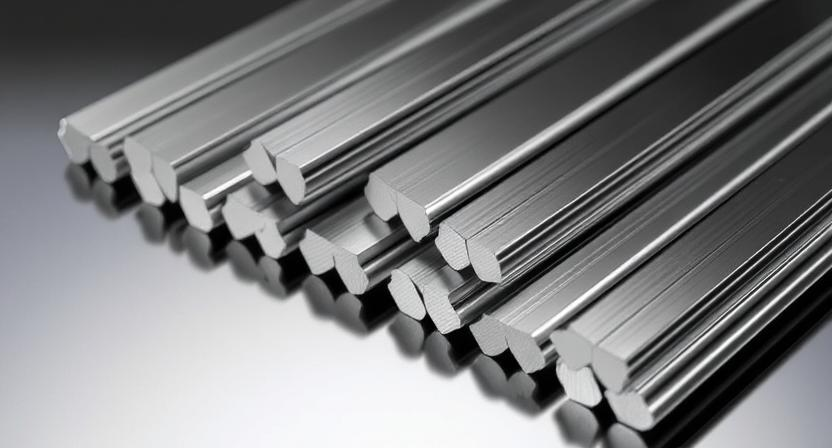

Stainless Steel 310 is an austenitic alloy known for its excellent oxidation resistance, exceptional resistance to corrosion, and high-temperature strength. It is often used in environments where high heat resistance is required, including furnaces, boilers, heat exchangers, and other high-temperature equipment. Stainless Steel 310 forged discs are precisely engineered circular components used in various applications, including machinery, pressure vessels, and other heavy-duty environments that demand durable, high-strength materials.

Ferrobend's Stainless Steel 310 forged discs are made using state-of-the-art forging techniques, ensuring consistency in quality and performance. The forging process provides superior mechanical properties, including enhanced strength and durability, making these discs suitable for extreme conditions, such as high-pressure, high-temperature, and corrosive environments.

At Ferrobend, we prioritize precision, quality, and reliability in all of our manufacturing processes. Our team of experts ensures that every Stainless Steel 310 forged disc is produced to exact specifications, meeting the highest standards of performance and durability. Here’s how we guarantee excellence

Ferrobend uses the latest forging techniques to manufacture Stainless Steel 310 forged discs. Our forging process involves heating the material to high temperatures and applying pressure to shape the discs into precise forms. This results in a superior grain structure, enhancing the material's strength and resistance to fatigue. The forging process also reduces internal stresses, ensuring better mechanical performance.

Ferrobend is committed to delivering high-quality products. Our Stainless Steel 310 forged discs undergo stringent quality control measures, including dimensional checks, surface inspections, and testing for mechanical properties. Each disc is carefully examined for any signs of defects, and only those that meet our strict standards are shipped to customers.