Stainless Steel 310 Socket Weld Pipe Fittings

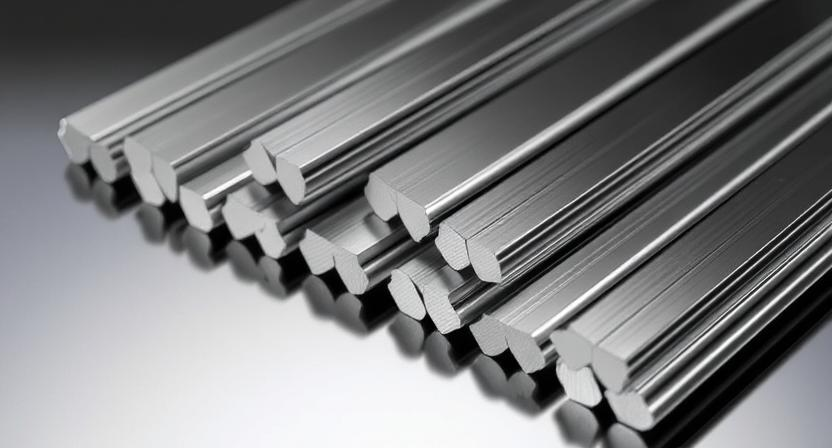

Stainless Steel 310 Socket Weld Pipe Fittings, known for their exceptional strength, corrosion resistance, and durability. Ferrobend, a leading manufacturer in the industry, specializes in the production of these high-performance pipe fittings. This article will delve into the details of Stainless Steel 310 Socket Weld Pipe Fittings, the manufacturing process by Ferrobend, and why these fittings are an essential choice for industries requiring reliable and robust piping solutions. Stainless Steel 310 is a high-alloy steel that contains high amounts of chromium and nickel, making it highly resistant to oxidation and corrosion. Stainless Steel 310 is known for its exceptional performance at elevated temperatures, withstanding temperatures up to 1100°C (2012°F). This makes it ideal for applications involving heat resistance, like those in power plants, refineries, and chemical processing.

Socket Weld Pipe Fittings are designed to be used in piping systems where high-pressure resistance and a secure, leak-free connection are necessary. These fittings are commonly used in small to medium bore pipelines where the welding process creates a strong and tight seal. Socket weld fittings have a socket-like design, allowing the pipe to be inserted into the fitting and then welded for a permanent, high-strength connection. Ferrobend’s Stainless Steel 310 Socket Weld Pipe Fittings are engineered for maximum performance and reliability. They are used in demanding environments where thermal stress, corrosion, and high-pressure conditions are prevalent.

Ferrobend specializes in welding high-quality fittings using advanced techniques, ensuring that every weld is strong, uniform, and durable. The pipe is carefully inserted into the fitting, and then a socket weld is applied. This permanent bond is designed to be leak-free and resistant to pressure.

Once the fittings are welded, they undergo stringent quality control checks. Ferrobend conducts a series of tests to ensure that each Stainless Steel 310 Socket Weld Pipe Fitting meets the required standards for strength, durability, and resistance. These tests include dimensional checks, pressure testing, and corrosion resistance testing. Ferrobend adheres to international standards such as ASTM, ASME, and ISO, ensuring that all products are safe, reliable, and suitable for various applications.

Ferrobend’s dedication to using only the best raw materials, combined with our advanced manufacturing processes, ensures that every fitting is of the highest quality. We maintain strict quality control at every stage to guarantee durability and reliability. Ferrobend offers customizable fittings to meet the unique needs of our clients. We understand that every piping system is different, and we work closely with clients to design and manufacture fittings that are tailored to specific applications. We understand the importance of meeting deadlines in the fast-paced industrial world. Ferrobend is known for its ability to deliver high-quality products on time, ensuring that your projects stay on track.

Ferrobend is your go-to source for premium Stainless Steel 310 Socket Weld Pipe Fittings. Through our expert manufacturing process, we deliver products that meet the highest standards of quality, strength, and durability. Whether you are working in the oil & gas, chemical, pharmaceutical, or power generation industries, our fittings provide the reliability and performance you need. Choose Ferrobend for all your pipe fitting requirements, and experience superior products backed by decades of expertise and commitment to customer satisfaction.