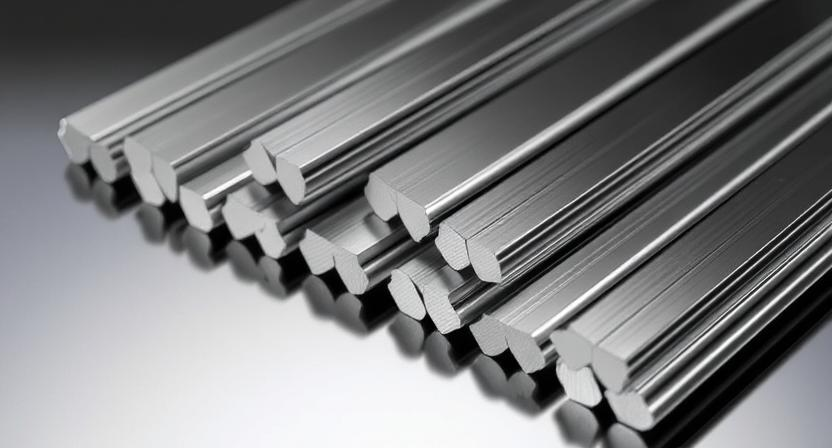

Stainless Steel 310 Filler Wires

Among the various types of filler wires available, stainless steel 310 filler wires stand out due to their remarkable high-temperature resistance, excellent oxidation properties, and superior durability. Ferrrobend, a leading manufacturer in the welding industry, specializes in the production of premium-quality stainless steel 310 filler wires, offering a reliable solution for a variety of industrial applications. Due to their excellent resistance to heat, stainless steel 310 filler wires are widely used in applications like furnace construction, kilns, heat exchangers, and thermal power plants. These filler wires ensure that joints and welds can withstand high temperatures without losing their structural integrity. The aerospace sector relies on materials that can withstand extreme environmental conditions, including high heat. Stainless steel 310 filler wires are commonly used in the repair and maintenance of aircraft parts exposed to high heat during flight.

Stainless steel 310 filler wires are engineered to withstand temperatures up to 1,150°C (2,100°F), making them ideal for use in environments where heat is a significant factor. The alloy's high chromium and nickel content offer superior resistance to oxidation, ensuring that welds remain intact even when exposed to extreme conditions.

Welds made with stainless steel 310 filler wires exhibit excellent strength and durability. These filler wires ensure that the welded joints maintain their mechanical properties over extended periods, even when subjected to thermal cycling, pressure, and chemical exposure. This longevity translates to lower maintenance costs and reduced downtime for industrial equipment.

Ferrrobend’s stainless steel 310 filler wires are suitable for a variety of welding techniques, including TIG

(Tungsten Inert Gas), MIG (Metal Inert Gas), and stick welding. This versatility ensures that fabricators can

use the wires in a broad range of welding environments, increasing their overall efficiency and productivity.

Ferrrobend begins the process by sourcing high-grade stainless steel alloy for the production of 310 filler

wires. The alloy must meet strict specifications to ensure that it has the correct balance of chromium,

nickel, and other alloying elements necessary for high-temperature resistance and corrosion resistance.

Stainless steel 310 filler wires from Ferrrobend are the go-to solution for industries that require high-temperature resistance, corrosion resistance, and durability. Whether for applications in power generation, aerospace, chemical processing, or food processing, Ferrrobend ensures that its stainless steel 310 filler wires meet the highest standards for performance, longevity, and quality. With advanced manufacturing processes and a commitment to customer satisfaction,